Learn How To Make Eco-Friendly Bricks

Wondering How To Make Eco-Friendly Bricks? Well, you’ve come to the right place! In this article, we will guide you through the process of creating environmentally friendly bricks that are not only strong and durable but also sustainable.

By using innovative materials and techniques, you can contribute to reducing the carbon footprint of construction while still achieving the desired results. Let’s dive in and explore the fascinating world of eco-friendly brick-making!

How to Make Eco-Friendly Bricks:

Bricks have long been a staple in the construction industry, but as we become more conscious of our impact on the environment, finding eco-friendly alternatives becomes crucial. Traditional bricks are typically made from clay, which requires extensive mining and processing, contributing to deforestation and carbon emissions. In contrast, eco-friendly bricks use sustainable materials and manufacturing processes to reduce their environmental footprint.

In this article, we will explore various methods and techniques for making eco-friendly bricks. We’ll delve into the benefits of using alternative materials, discuss different production methods, and highlight the importance of sustainable practices. So let’s get started on this journey towards greener construction!

The Benefits of Eco-Friendly Bricks

Eco-friendly bricks offer several advantages over traditional bricks, including:

1. Sustainability: Eco-friendly bricks use renewable or recycled materials, reducing the demand for natural resources.

2. Energy Efficiency: These bricks often have better insulation properties, leading to reduced energy consumption in buildings.

3. Reduced Carbon Footprint: By utilizing sustainable materials and manufacturing processes, eco-friendly bricks emit fewer greenhouse gases.

4. Healthier Living Spaces: Some eco-bricks are designed to improve indoor air quality and mitigate the risk of health issues like mold growth.

5. Innovative Design Opportunities: The use of alternative materials in eco-bricks allows for unique and creative architectural expressions.

Materials for Eco-Friendly Bricks

To create eco-friendly bricks, various materials can be used, each offering its unique benefits. Let’s explore some of these options:

1. Fly Ash Bricks

Fly ash is a byproduct of burning coal in power plants. Instead of disposing of this waste material, it can be used as a substitute for cement in brick production. Fly ash bricks are not only eco-friendly but also possess excellent strength and durability.

2. Rice Husk Ash Bricks

Rice husk ash, another waste material, can be mixed with lime and cement to produce bricks with good thermal insulation properties. These bricks are lightweight, reduce energy consumption, and provide excellent sound insulation.

3. Hempcrete Bricks

Hempcrete is a biocomposite material made from the woody core fibers of the hemp plant, lime-based binder, and water. Hempcrete bricks have impressive thermal insulation properties, are non-toxic, and have a negative carbon footprint.

4. Recycled Bricks

Using reclaimed or recycled materials, such as crushed concrete, glass, and plastic, in brick production helps divert waste from landfills. These bricks are sturdy, cost-effective, and reduce the demand for virgin materials.

5. BioBricks

BioBricks are made from agricultural waste, such as straw, corn husks, or sawdust. These materials are mixed with a natural binder, such as starch or soy, to create bricks that are lightweight, have good insulation properties, and are biodegradable.

Methods of Eco-Friendly Brick Production

1. Compressed Earth Bricks

Compressed earth bricks are made by compressing a mixture of clay, sand, and stabilizers into a desired shape. This method eliminates the need for firing or baking the bricks, reducing energy consumption and carbon emissions.

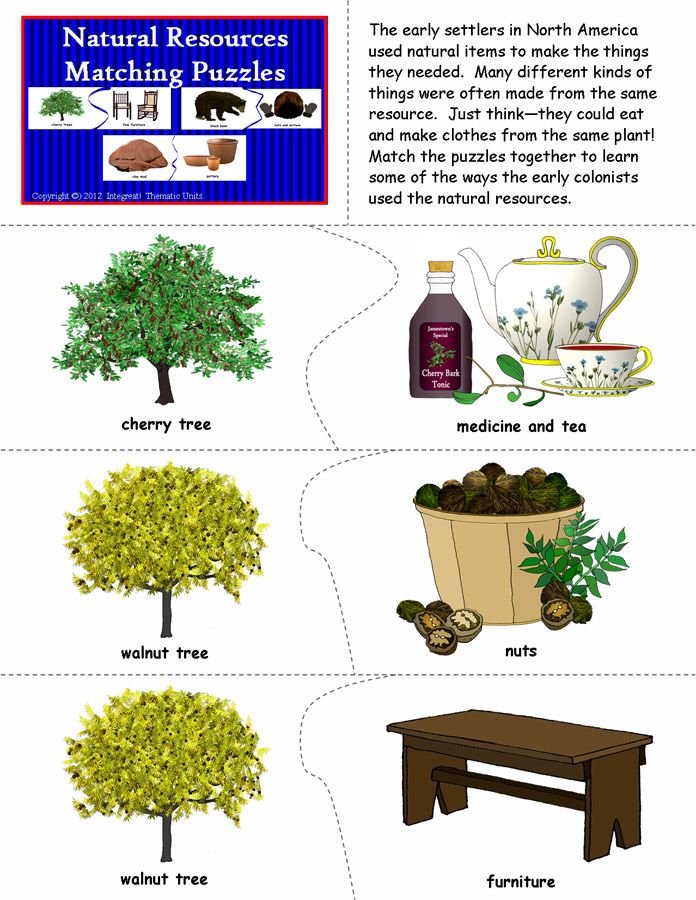

2. Modular Bricks

Modular brick production involves using reusable molds to create interlocking bricks that fit together like puzzle pieces. These bricks require less mortar and reduce material waste during construction.

3. Lime Stabilized Bricks

In lime stabilized brick production, lime is used as a binder instead of cement. Lime has lower carbon emissions during production and contributes to better thermal and sound insulation properties.

4. 3D Printed Bricks

3D printing technology is revolutionizing the construction industry, allowing for the production of bricks with intricate designs and reduced material waste. These bricks can be printed using sustainable materials like recycled plastic or clay.

5. Ferrocement Bricks

Ferrocement bricks are made using a thin layer of cement mortar reinforced with a mesh of steel wires or fibers. This method reduces the amount of cement used, leading to lower carbon emissions and increased flexibility in design.

Sustainable Practices in Brick Production

To further enhance the eco-friendliness of brick production, it’s essential to adopt sustainable practices throughout the manufacturing process. Here are some key considerations:

1. Efficient Energy Use

Implementing energy-efficient technologies and using renewable energy sources in brick kilns can significantly reduce carbon emissions and energy consumption.

2. Water Conservation

Using water-efficient techniques like recycling and rainwater harvesting helps to minimize water consumption in brick production.

3. Waste Management

Proper waste management, such as recycling and reusing, should be integrated into brick production processes to minimize environmental impact.

4. Environmental Certifications

Obtaining environmental certifications, such as LEED (Leadership in Energy and Environmental Design), ensures compliance with sustainable standards and promotes eco-friendly practices.

5. Local Sourcing

Opting for locally sourced materials reduces carbon emissions associated with transportation and supports local economies.

Incorporating eco-friendly bricks into construction projects is a significant step towards sustainable and environmentally conscious building practices. By leveraging alternative materials and adopting sustainable production methods, we can reduce the ecological impact of traditional brick manufacturing while creating healthier and more energy-efficient structures.

Frequently Asked Questions

What materials are used to make eco-friendly bricks?

Eco-friendly bricks are made using a combination of natural materials such as clay, soil, sand, and water. These materials are mixed together to create a homogeneous mixture that is molded into brick shapes. Some eco-friendly bricks also incorporate recycled materials like fly ash, rice husks, or sawdust to enhance their sustainability.

Why are eco-friendly bricks considered environmentally friendly?

Eco-friendly bricks are considered environmentally friendly because they utilize natural materials and often incorporate recycled content. They have a lower carbon footprint compared to traditional bricks as they require less energy during production. Additionally, these bricks offer better insulation properties, reducing the energy consumption needed for heating or cooling buildings.

What is the manufacturing process for eco-friendly bricks?

The manufacturing process for eco-friendly bricks typically involves mixing the raw materials thoroughly, adding water to form a workable consistency, and then molding the mixture into brick shapes. The bricks are then allowed to dry naturally or may undergo low-temperature kiln firing. This process ensures minimum energy consumption and reduces pollution.

Are eco-friendly bricks as durable as traditional bricks?

Eco-friendly bricks can be just as durable as traditional bricks, provided they are manufactured and cured properly. By using high-quality natural materials and appropriate manufacturing techniques, eco-friendly bricks can meet the required strength and durability standards for construction purposes. It is essential to follow recommended guidelines during the production process to ensure the longevity of these bricks.

What are the advantages of using eco-friendly bricks in construction?

Using eco-friendly bricks in construction offers several advantages. Firstly, they contribute to reducing the environmental impact by utilizing natural materials and minimizing energy consumption during production. Eco-friendly bricks also provide better thermal insulation, reducing energy costs over time. Additionally, these bricks have a versatile aesthetic appeal and can be used for various construction projects, enhancing sustainability in the building sector.

Can eco-friendly bricks be recycled or reused?

Yes, eco-friendly bricks can be recycled or reused. Since they are made using natural materials, they can be crushed and used as aggregates in new brick production or as fillers in other construction materials. Recycling or reusing eco-friendly bricks helps minimize waste and further reduces the environmental impact associated with brick manufacturing.

Final Thoughts

In conclusion, making eco-friendly bricks is a sustainable solution for reducing environmental impact in the construction industry. By incorporating materials such as fly ash, recycled aggregates, and bio-based binders, the production of these bricks significantly reduces carbon emissions and minimizes waste. The use of renewable energy sources during the manufacturing process further enhances their eco-credentials. Additionally, these bricks possess comparable strength and durability to traditional bricks, making them a viable alternative for construction projects. Implementing eco-friendly brick production techniques is an essential step towards creating a more sustainable and greener future for the building sector.