eco friendly plastic bags

eco friendly plastic bags over cotton sacks

The plastic bags from the Bengaluru office’s 500 kgs a day food waste are recycled in another Rs 6 lakh worth business every year, “There is no better use for them than packaging food,” explains finance manager Hari Praveen.

But all good things have to end. In January, the company had to stop using the sustainable bags.

Unlike last year when it increased its monthly manufacturing capacity to 300 kgs from 200 kgs, the move this year was due to the supply of waste plastic bags. According to Hari, the demand for both of these bags has shrunk after the ban came into effect. However, he says the city has recorded about 60% drop in prices for the first six months of the year. “Since we are low on stock, we started stocking our factory with cheaper options such as cotton sacks. Earlier we used to sell the bags at about Rs 100 for 500 ml; now we are selling the same quantity at around Rs 30. These have more volume,” he adds.

The company will be exporting its 500 kgs of biodegradable plastic bags to the US for marketing to major supermarkets. This is the first time it has sold the bags outside India.

FOSSIL-FREE PACKAGING

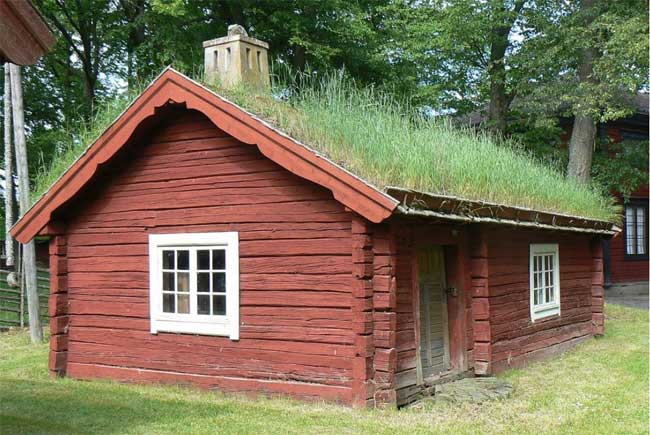

Founded in the year 2000, Wang’s Eco Packaging uses plant-based or natural materials as packaging materials to make small machines that are used in tissue paper industry. The company uses cotton and coir fibre bags, food waste from various restaurants as packaging material for their products, while waste plastic from Bengaluru office is also recycled and used for packaging.

The coir bags are a cost-effective alternative to polyethylene, says co-founder Abhishek

The company buys food waste from Bengaluru restaurants on a monthly basis to make a 100-150-kg order. The company aims at at least 2,000 tonnes of food waste to be collected annually. “We transport the food waste to the landfills and collect it by carting in trash,” says Abhishek, adding that they had once tried making plastic bags using the recycled plastic, but faced challenges due to processing and inflexibility in creating plastic bags from rice husk fibre.

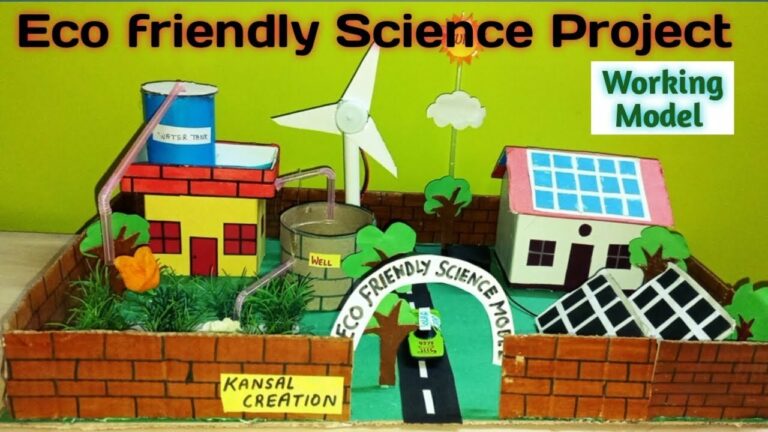

Abhishek and his team have managed to set up the WEP Automation Pvt Ltd at the Greens to Go Park and Resource centre. WEP Automation makes other eco-friendly products using waste plastic such as motor, plastic propeller, tri-blades, rubber pedals, watertight oilcan, windshield wipers, and several more, which are exported to Germany and the US.

The company uses 95% bio-degradable materials, mostly made from non-edible by-products of the potato processing industry. Besides providing waste plastics to the restaurant owners, they have also started a waste management project called The Green Kitchen.

To start, they started with a five-tonne order from the IRCTC. Currently, they receive 10-15 tonne orders from the restaurant owners. As part of their mandate, they try to ensure that their food waste products are disposed of in an eco-friendly manner.

THE BENEFITS:

Many of the restaurant owners are satisfied with the product. Bhavya Shah, manager, Arihant, says the coir bags for the smaller utensils are an ideal size. They are cheaper and can be reused for months. Koushik M, general manager, Cuisine of KFC, claims the bags are durable and biodegradable.

“We get an order for 500 pieces of utensils every month, and we sell them with a sticker that shows they have been recycled from used food waste,” says Abhishek.

THE TURNING POINT:

The company came into existence after a Belgian delegation visited Wang’s Eco Packaging and realised that the waste plastic could be used for packaging and other similar products. Abhishek says the new orders for utensils are sufficient to meet their business requirements.

THE NEED:

More companies are looking to sell their waste plastic products, and are using it as alternative packaging material. Abhishek has written to the ministries of power and agriculture and is in talks with manufacturers and eateries across Bengaluru to set up facilities to convert waste plastic into packaging.

“Even if we sell all the plastic produced, we will only be able to process half of the existing waste,” he says.

He also wishes that the city would come up with a more organised and efficient waste management system to make available a better quality of raw material, to help companies produce eco-friendly products and packaging.